China has actively responded to the COVID-19 outbreak and made great achievements. However, the current epidemic situation is still grim and complex, and the prevention and control of the disease is at the most critical stage. As enterprises resume work and production, under the leadership and command of governments at all levels, they will continue to focus on prevention and control work. Therefore, improving production quality, avoiding waste products and improving production efficiency, and saving non-production time for quantification have become important requirements to ensure enterprise benefits.

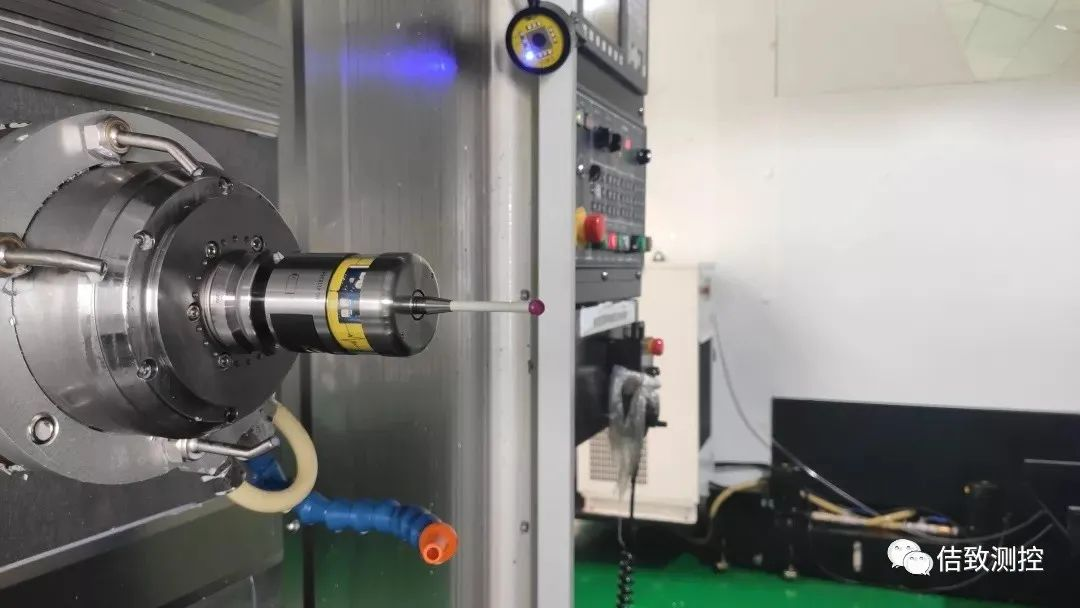

Machine tool probes are generally installed on CNC lathes, machining centers, CNC grinders and other CNC machine tools. It can directly measure the size and position of the tool or the workpiece without human intervention in the processing cycle, and automatically correct the bias of the workpiece or the tool according to the measurement results, so that the same machine tool can process higher precision parts.

The main function of machine tool probe is to help machine tool measurement and processing correction. It has the following functions.

1.Automatic identification of machine tool accuracy error, and automatic compensation of machine tool accuracy;

2.Instead of manual automatic center, edge finding, measurement, and according to the measurement data automatic correction coordinate system, automatic tool complement;

3. Measurement of the direct marching curve surface of the workpiece;

4. Automatically compare the measurement results and report.

To sum up, it can be seen that the machine tool probe because it is directly installed on the machine tool, and can automatically measure, automatically record, automatically calibrate, to reduce the processing process, reduce labor cost, and less investment, to improve the machine tool processing accuracy and efficiency has a positive role.

Post time: Nov-21-2022